A “Simple” Look at Definitions:

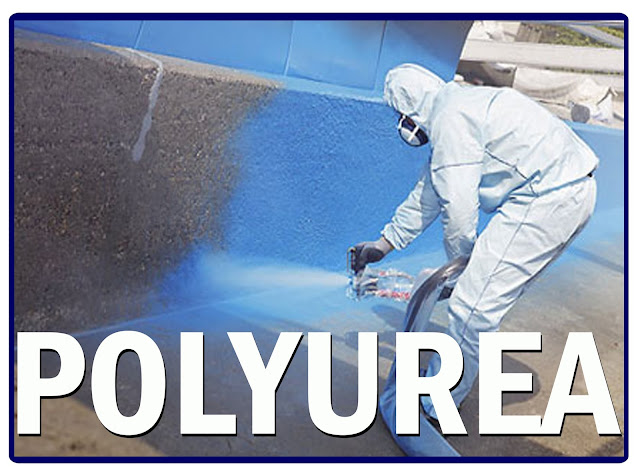

Polyurea-

Polyurea can be defined as the effect of a chemical response between an isocyanate and an amine. In chemical coating terms, this is generally a reaction between an MDI or HDI pre-polymer with amine-terminated resins. This is also the formally excluded definition by the PDA. The PDA also supports the use of pigment dispersals in polyols (these are generally used as colorants) assuming correct stoichiometric calculations have been used. These amines are generally composed of polyetheramines and an elemental anime string-extender which is used to impart hard block content and place the formulation on a 1:1 by volume ratio. Polyurea coatings can also be composed of aspartic esters which provide amine functionality. A polyurea offers a chemical backbone containing amine linkages. Polyurea is commonly used as an industrial coating in strict environments with excellent chemical resistance to hydrocarbons and hydrogen sulfide gas and immersed sewage applications.

Polyurethane-

Polyurethane can be described as the result of a chemical response within an isocyanate and a polyol. It is essential to realize that polyurethane requires the employment of a catalyst to complete the reaction promptly. As with polyureas, a pigment disbanded in a polyol is generally utilized for the colorant. These formulations require typically various volume ratios and ambient heats. Usually, these formulations have no amines in the polymer backbone. All functionality is contemplated to be hydroxyl (i.e., containing alcohols). Polyurethanes are generally recognized as casting materials and foams. They show good longevity and are relatively inexpensive.

Polyurea/Polyurethane Hybrid-

Polyurea/Polyurethane hybrid formulations can be explained as the result of a chemical reaction within an isocyanate and a blend of polyol and amine reactants. These formulations frequently provide an “intermediate” polyurea that represents many of the same properties of a polyurea. Nevertheless, hybrid formulations can also present some of the negative obstacles associated with polyurethane chemistry. In coatings formulation, hybrids frequently contain a polyether/polyester polyol and a primary amine happening in a chemical backbone composed of amine and hydroxyl functionality. Polyurea/polyurethane hybrids are regularly associated with use on “non-critical” items that generally do not demand immersion or extreme temperature circumstances for the application. Some examples of these applications involve sprayed-in truck bed linings and balcony deck coatings.

For a more in-depth review on the differences between the products, please go the article section of ArmorThane’s Website.